Compressed Air Storage Tank Safety Program

Purpose

The purpose of this safety policy and procedure is to establish guidelines for the protection of [COMPANY] employees working with or on compressed air equipment. Air compressors are used for a variety of applications in [COMPANY]. Air compressor storage tanks store excess air that is generated from the compressor. Thus, air compressor storage tanks provide a convenient and readily accessible air source. However, because of the air pressure within these storage tanks, potential dangers can develop if certain practices and precautions are not followed.

This safety policy and procedure provides guidelines for the safe use of air compressor storage tanks. It includes provisions for training, discussion on where these air compressor storage tanks are used, and guidelines for locating drains and traps on air compressor storage tanks. Additionally, it presents requirements for gauges and valves and installation of gauges, valves, drains and traps.

[COMPANY] will not tolerate malfunctioning air compressor storage tanks that are a threat to employee safety. When these hazards exist that cannot be eliminated, then engineering practices, administrative practices, safe work practices, Personal Protective Equipment (PPE), and proper training regarding Air Compressor Storage Tanks will be implemented. These measures will be implemented to minimize those hazards to ensure the safety of employees and the public.

Responsibilities

Managers/Unit Heads are responsible for ensuring that adequate funds are available for the purchase and repair of air compressor storage tanks in their areas. Additionally, they will be responsible for identifying the employees affected by this safety policy and procedure. Managers/Unit Heads will obtain and coordinate the required training for affected employees. Managers/Unit Heads will also ensure proper use and maintenance through regular standard audits of air compressor storage tanks.

Supervisors will ensure that only those employees who have been trained to work with air compressor storage tanks will be allowed to operate such equipment. Supervisors will ensure that equipment as needed is available and is in good working condition. If the equipment is not in good working condition, they will ensure that such equipment is repaired. Supervisors will ensure that air compressor storage tanks are inspected every six months and that employees are provided with Personal Protective Equipment (PPE) as necessary for their job. Appendix A provides a generic checklist for use by supervisors.

Employees will inspect air compressor storage tanks prior to use and note any damage or defects. Employees shall immediately report any damages or defects to their supervisors. Employees will empty manual drains and taps on a regularly scheduled basis.

Safety Department will provide prompt assistance to managers/unit heads, supervisors, or others as applicable as necessary on any matter concerning this safety policy and procedure. Additionally, Safety will assist in developing or securing required training. Safety will also work with Purchasing to ensure that all newly purchased air compressor storage tanks comply with current safety regulations. Safety will provide consultative service and audit assistance to ensure effective implementation of this safety policy and procedure.

Definitions

Air Compressor Storage Tank - Pressurized vessel that stores air generated from an air compressor.

Drain Valve - A valve that is installed at the lowest point of an air compressor storage tank to provide for the removal of accumulated oil and water.

Trap - A device which uses venting head pressure to purge the tank from condensed water.

Training

Affected employees will be trained in:

• The purpose of air compressor storage tanks

• The basic operation of air compressor storage tanks

• Maintenance requirements of drains and traps

• Reading gauges and operating valves

• Identifying damage and defects in the storage tanks

This training shall be performed upon initial employment and/or job reassignment. Periodic refresher training shall also be conducted at the discretion of the supervisor.

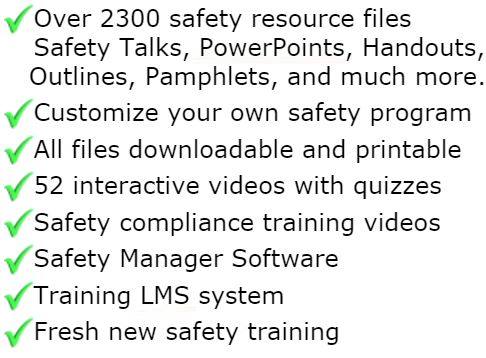

GET INSTANT ACCESS

to THE MEMBERS LIBRARY

Safety materials created by safety professionals.

Access to the Safety Manager software.

Wide variety of safety videos and courses.

**Brand New** Safety Training Management System

Pre-Made Safety Materials Ready For Use

Created by experienced safety professionals & risk consultants. Saving you time, money, and risk of injuries.

95% of the work already done.

Below are the maximum penalty amounts, with the annual adjustment for inflation, that may be assessed after Jan. 15, 2024. (See OSHA Memo, Jan. 8, 2024).

**New OSHA HEAT 90 DAY**

>>Download Free HERE<<

**New 2024 OSHA 300 Form**

>>Download Free HERE<<

**Brand New**

Free with full membership subscription

Training LMS System

Ask The Safety Consultant

Safety Equipment Deal Finder

-Mike McKenzie, Certified Safety & Health Manager (CSHM), McSafety Solutions™

Note: You must have a full subscription to the Safety Library in order to use this material. Any use outside of your organization, for resell, or without an active membership is strictly prohibited and may result in prosecution under copyright infringement laws. Please contact us first, if you would be interested in reselling or using our materials for reproduction.

Inside the Members Library

Topic Index

Accident Prevention

Air Quality

Asbestos

Bloodborne Pathogens

Boilers

Chemical Safety

Compressed Gas

Confined Space

Construction

Construction Worksite

Cranes & Slings

Driver / Fleet Safety

Drug Free Workplace

Electrical

Emergency Management

Engineering Safety

Environmental

Equipment

Ergonomics

Fall Protection

Fire Safety & Prevention

First Aid

Flammable Materials

Forklifts

Hazard Communication

Hazardous Materials

Hearing Protection

Heat Stress

Hot Work

Housekeeping

Job Safety Analysis

Laboratory

Ladders

Lead

Lockout-Tagout

Machinery & Equipment

Material Handling

MSDS (SDS)

Medical & First Aid

Occupational Health

Office Safety

Off the Job Safety

Personal Protection

Process Safety

Record Keeping

Respiratory Protection

Silica Safety

Rules & Policies

Signs & Labels

Slips, Trips & Fall

Training

Terrorism Programs

Tool Safety

Vehicle & Driver

Violence Programs

Welding & Hot Work

Training Videos

Library Index

Training Materials

Videos/Courses

Talks

Articles

PowerPoint

Handouts

Training Overheads

Quizzes

Supervisor Briefs

Management Briefs

Safety Sessions

2 Minute OSHA Safety Talks

Pamphlets

First Aid Training

Supervisor Training

Hazardous Materials

Bomb Threat

Crossword Puzzles

Biological Agents

Forms & Documents

Forms

Checklists

Audit Guides

Inspections Guides

Signs & Labels

Environmental Audit Guides

Recordkeeping - OSHA 300

Sign & Label Maker

Safety Management Resources

Safety Manuals/Written Programs

Ergonomic Programs

Emergency Plans

Process Safety Management

Construction Safety

Occupational Health

Environmental

Topic Sheets

DOT Fleet-Driver

Hazardous Materials

Chemical Safety

Drug Free Workplace

Terrorism Programs

Development Guides

Safety Manager Software

Safety References & Graphics

Technical Safety Information

Posters

Topic & Fact Sheets

Development Information

Job Specific Safety Rules

Terrorism

Calculators

Safety Comic Strips

New Safety Training System

Schedule and train your employees with our materials. Add unlimited amount of employees. Record all progress and issue certificates. For group and individual training sessions.